生物活体材料,如动物骨骼和植物茎,能够在环境压力下自我修复、再生、适应和做出决定。尽管最近成功地为合成材料注入了其中一些非凡的功能,但在生物学中发现的复杂适应性系统的许多新兴特性仍未在工程生物材料中探索。在这里,荷兰代尔夫特理工大学航空航天工程学院Masania教授等描述了一种三维打印方法,该方法利用真菌菌丝体的新兴特性来创建活的复杂材料,这些材料可以自我修复,再生和适应环境,同时实现工程功能。装有真菌灵芝的水凝胶被三维打印到晶格结构中,以使菌丝体生长在平衡的探索和开发模式中,同时促进凝胶的定植和气隙的弥合。为了说明这种基于菌丝体的活体复合材料的潜力,我们三维打印了一种机械坚固,自清洁并且能够在损坏后自主再生的机器人皮肤。

图文解读

使用接种菌丝体的水凝胶3D打印活的复杂材料。该工作流程包括混合含有麦芽提取物和流变改性剂的琼脂基水凝胶以获得颗粒墨水,将真菌沉积在这种颗粒墨水的顶部,最后去除真菌顶层以创建富含菌丝体的原料,用于通过直接墨水写入进行3D打印(图 1a)。原料油墨被印刷成机械稳定的网格状结构,提供菌丝体生长所需的开放空间和营养物质。在环境温度和高相对湿度下孵育打印对象允许菌丝体在沉积的细丝内和之间生长,而不会干燥水凝胶结构。可以利用3D打印的成型能力来制造几何形状的复杂材料,以满足特定工程场景的功能要求。这一概念的一个可能体现是为机器人创造保护性活皮。为了实现此功能,皮肤应具有机械强度,但也应足够活跃,以使受损部位自我再生。这种明显矛盾的特征可以通过将含有菌丝体的水凝胶3D打印到自然界中不存在的工程结构中来实现(图1b)。在这些结构中,机械坚固性源于形成强大的纤维菌丝体网络,其形状与最终应用相关。活性和自我再生受损位点的能力来自菌丝体细胞的代谢活动,菌丝体细胞在自然界中进化为在多孔结构的开口内导航和生长。活的复杂材料的最终功能最终通过独特的分层结构实现,该结构从单个菌丝体细胞到菌丝网络和网格状结构,形成设计师宏观几何形状(图1b)。

Fig. 1 Living complex materials and objects made by 3D printing of mycelium-laden hydrogels. a, Schematics displaying the distinct steps of the 3D-printing process, from the preparation of inks with inoculated mycelia (left), to the direct ink writing of mycelial hydrogels into grid architectures (middle), to the growth of the fungus through the phalanx or guerrilla strategy depending on the nutrient concentration (right). b, Hierarchical structure of the resulting mycelium-based objects, highlighting (from left to right) the cell-level growth through self-organization processes, the hyphal cells that form the mycelial network, the growth of the mycelial network between printed hydrogel filaments, the self-healing and regeneration processes across large air gaps and the macroscopic geometry of the complex material according to the shapes that are relevant for the final applications.

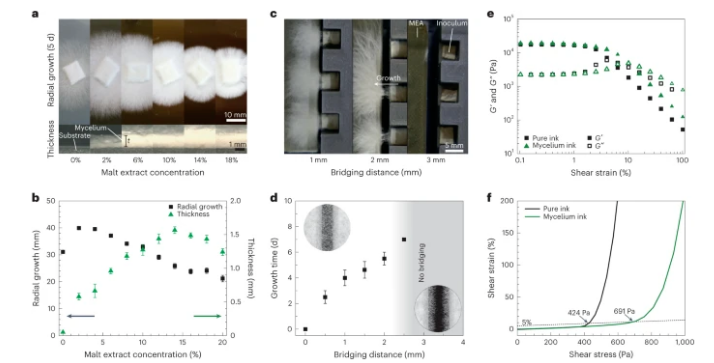

为了创建拟议的基于菌丝体的活体复杂材料,我们首先确定了制备可打印菌丝体水凝胶和网格状结构中预期间隙之间的真菌生长所需的条件。通过研究沉积在琼脂基水凝胶基质物顶部的真菌的生长行为,评估导致高菌丝体浓度的水凝胶油墨的加工条件(图2a,b)。为此,将一块矩形真菌接种物放置在基质表面上,并在23°C和95%的相对湿度下生长。通过在具有不同初始浓度的麦芽提取物的水凝胶上沉积五天后测量真菌的径向和厚度膨胀来量化生长。结果表明,菌丝体生长受到底物中可用麦芽提取物浓度的强烈影响(图2b)。低浓度有利于真菌的径向扩张,而表面菌丝层厚度的增长有限。与在含有2-4%麦芽提取物的凝胶上培养的凝胶相比,放置在麦芽提取物含量为65-15%的凝胶上的真菌的径向生长大约20%。沉积在含有这些高麦芽提取物含量的水凝胶上的真菌不是径向膨胀,而是倾向于在凝胶上生长更厚的层。事实上,我们的数据显示,当初始麦芽提取物浓度从1%变为7%时,真菌在水凝胶上的垫子会长出2.14倍厚的垫子。对于网格状结构,印刷油墨应具有足够高的存储模量,以防止长丝下垂和高屈服应力,以最大程度地减少毛细管和重力驱动的形状变形。使用振荡流变学,我们发现在剪切应变低于1%时,用菌丝体接种基础油墨不会改变其粘弹性(存储(G′)和损失(G“)模量)(图2e)。然而,剪切应力-应变测量表明,菌丝体的存在使基础油墨的屈服应力从大约400 Pa增加到近700 Pa(图2f)。

Fig. 2. Fungal growth behaviour and rheology of mycelium-laden hydrogels. a,b, Growth in radius and thickness (t) after five days of mycelia inoculated on the surface of agar gels containing varying concentrations of malt extract. The rectangular samples consist of pieces of agar hydrogel with pre-inoculated mycelia. The data shown in b represent the mean values obtained from five different samples. c,d, Bridging of mycelia across air gaps intentionally formed between the surface of inoculated agar gels. The time that it takes for the mycelia to bridge an air gap of defined length is shown in the plot (d). The data represent the mean values obtained from five different samples. e, Storage (G′) and loss (G″) moduli of mycelium-laden hydrogel ink as a function of the applied oscillatory strain. f, Flow behaviour of the mycelium-laden hydrogel ink, highlighting the yield stress below which no substantial deformation takes place. The rheological behaviour of a mycelium-free ink is also shown in e and f for comparison. Error bars represent the standard deviation of five measurements of distinct samples at each data point.

使用基于桌面挤出的打印机将具有最佳流变特性的菌丝体墨水3D打印到稳定的网格状架构中。使用不同的油墨配方和可编程的印刷路径制备具有不同长丝间距、直径和麦芽提取物浓度的网格。将这些印刷网格孵育长达20天,允许水凝胶丝之间的菌丝体有效生长,从而形成机械坚固的活结构(图3a,b)。通过测量研磨和在水中广泛洗涤网格后剩余的干燥生物量的相对量来量化菌丝体随时间的变化。结果表明,菌丝体的干质量最初为零,并且在孵育的前十天内线性增长至约4-5wt%,之后发现生物量趋于平稳(图3c)。这种行为表明,这些实验中使用的10%麦芽浓度足以在前十天内诱导稳定的菌丝体生长,但在此时间窗口之后,营养物质最终会从培养基中耗尽。

细丝之间菌丝体的生长产生了一种强大的基于真菌的活材料,与最初的基于水凝胶的网格相比,它具有很强的抗撕裂、拉伸和压缩能力。我们通过对孵育不同时间段的试样进行压缩实验来量化网格的刚度(图3)。从这些测量中获得的典型应力-应变曲线显示,随着施加应变的增加,网格不断变硬。将应力-应变数据的斜率作为材料的瞬时弹性模量(图3d),我们发现网格在单轴压缩时经历了连续的刚度过程。原位成像表明,在第一次加固过程中,沿样品高度的相邻细丝仍被菌丝体隔开,但最终在第二次加固事件发生时相互推入。随着压缩和致密化的进行,网格继续急剧变硬,直到最终断裂,伴随着样品中液体的突然爆发。

为了更好地了解真菌网络对菌丝体基生物材料的力学性能的作用,我们测量了网格的弹性模量作为生长时间的函数(图3e)。随着孵化前十天的稳步增加,网格的刚度直接反映了菌丝网络的生长曲线。实际上,观察到测量的刚度与微生物产生的干生物量直接成比例(图3f)。这表明复杂材料的弹性模量由网格细丝之间形成的菌丝网络的承载能力决定。网格刚度与产生的干燥生物质之间的直接相关性也有助于解释麦芽提取物浓度和线间隙对网格弹性模量的影响(图3g,h)。对于用不同麦芽浓度制备的网格,我们发现过量的营养物质并不一定会导致网格内生物质浓度更高。这一发现可能与高糖含量降低水分活度的事实有关。

Fig. 3. Growth and mechanical stiffness of mycelium-based living material with 10% malt concentration. a, Photographs of the 3D-printed mycelium-based grids with increasing growth times. b, Cross-section of the grid after two and ten days of incubation, indicating the notable growth of mycelia in between the printed hydrogel filaments. c, Amount of biomass generated by the fungus as a function of time for grids printed with a line spacing of 2?mm and using a nozzle diameter of 0.84?mm (as shown in a and b). The data represent the mean values obtained from five different samples. d, Representative stress–strain curve obtained from the mechanical compression tests (black line) and the associated variation in instantaneous stiffness (red line). The insets show in situ images of the cross-section of the material at different applied strain levels. e, Apparent stiffness as a function of growth time for mycelium-containing grids printed with a line spacing of 2?mm and using a nozzle diameter of 0.84?mm (shown in a and b). f, Correlation between the apparent stiffness and the biomass concentration of grids shown in a and b. g,h, Apparent stiffness and biomass content of mycelium-laden grids printed with different gaps between the grid lines (g) and with hydrogels containing distinct malt extract concentrations (h). The apparent stiffness values reported in e–h correspond to the instantaneous elastic modulus at a strain value of 25%. The data represent the mean values and the standard deviation obtained from five measurements of distinct samples at each data point.

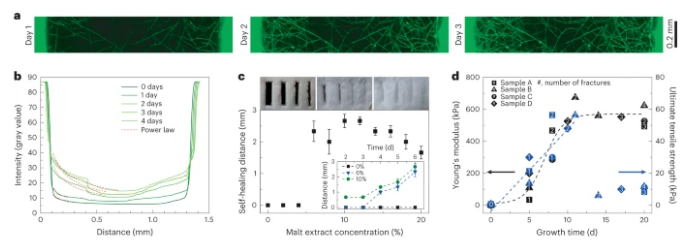

菌丝体网络的代谢活动赋予我们的3D打印物体非凡的生命和自我再生特性。我们通过首先在模型实验中研究微生物在物理分离表面和气隙中的生长行为来说明这些特性(图4a-c)。为了深入了解我们材料的活性,在激光扫描共聚焦显微镜中随着时间的推移,在两个充满真菌的水凝胶丝之间生长的菌丝网络进行了成像(图4b)。在这种设置中,将两个相距1.2毫米的墨丝打印到载玻片上,并用另一个薄载玻片覆盖,在两者之间留下一个气隙。使用荧光染料(钙荧光白)检测从丝表面生长的菌丝网络,该染料特异性吸附到菌丝细胞壁中存在的几丁质分子上。

Fig. 4. Livingness, self-healing and application of mycelium-based living materials. a, Laser confocal microscopy images of dyed mycelia (green) growing between two hydrogel filaments printed 1.2?mm apart. These images are representatives of a series of three experiments. b, Intensity profiles of the images shown in a quantifying the time evolution of the spatial distribution of the mycelial network grown between the two filaments. The decay in fluorescence intensity as a function of distance is fitted with a power law to demonstrate the scale-free nature of the network. c, Self-healing distance covered by the mycelia across a cut deliberately introduced into a mycelium-containing film prepared with different malt extract concentrations. The pictures shown as insets display a film with 10% malt extract after two, four and six growth days. The distance healed by the mycelia over time is also included as an inset for specimens with selected malt extract concentrations. The data represent the mean values and the standard deviation obtained from five measurements of distinct samples at each data point. d, Young’s modulus and the ultimate strength of samples subjected to multiple fracture–healing cycles during growth of the mycelium-based living material. e, Photographs of the tensile mechanical tests performed to demonstrate the self-healing ability of the mycelium-based material. f, Joining of 3D-printed parts into a single object through the growth of mycelia between surfaces in physical contact. g,h, Living skins printed on top of a robotic gripper (g) and an untethered rolling robot (h). Water droplets on the surface of the skin illustrate the hydrophobic nature of the mycelium-based living material. i, Snapshots of the skin covering the rolling robot before and after mycelial growth. Photographs of the rolling robot after friction-driven locomotion on different surfaces demonstrate the mechanical robustness of the living skin. j, Snapshots showing the underwater cooperative interaction between the robotic gripper and the untethered rolling robot protected by the living skin.

总结

将微生物的活性与3D打印技术的塑造能力相结合,是创造具有无与伦比的复杂适应性的功能性生物材料的有力途径。使用这种策略,可以将装有目标微生物的水凝胶塑造成满足功能设计的架构,并为生物物种的生长提供足够的环境。由此产生的结构的活特性来自嵌入水凝胶中的生物体的代谢活动。这种代谢活动使基于菌丝体的生命材料充满了复杂适应系统的几个特征,包括能够生长和再生的耗散自组织过程,跨多个长度尺度的构建块的分层组织,无尺度分形网络的最佳传输特性以及来自信息处理细胞的分散合作行动的决策能力。具有如此复杂适应性的真菌水凝胶的3D打印为创建用于多种应用的功能性菌丝体生命材料提供了独特的机会,并有可能激发其他策略,将生命带入材料领域。

中国能源资讯网

中国能源资讯网